Pioneering the future of Casting with Robotics & AI.

Our response to demographic change:

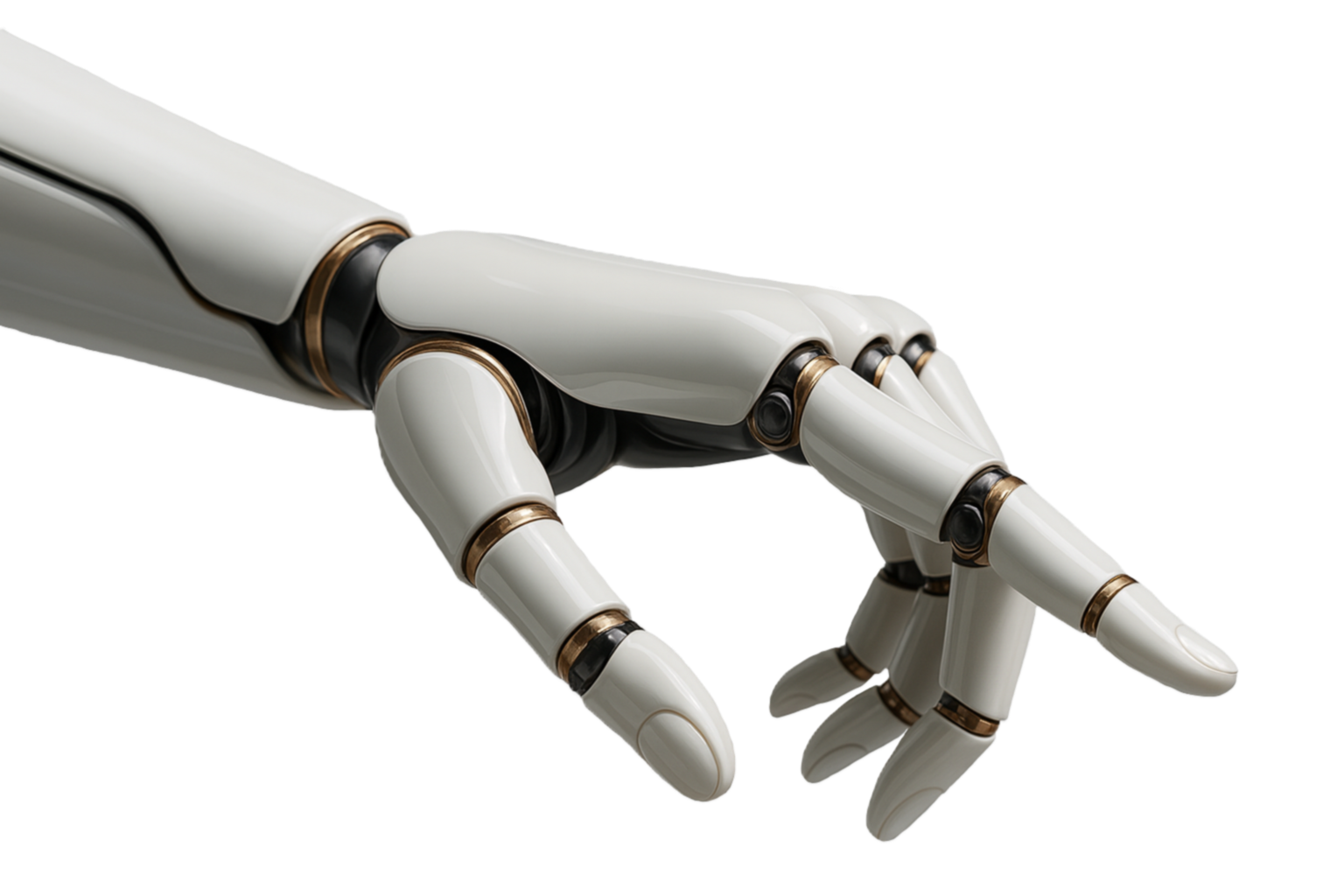

Industrial Artificial Intelligence (AI) – Robots with artificial intelligence for the casting industry. Experience in quality casting, state-of-the-art robotics, artificial intelligence, and a dynamic team. Our solutions make casting processes safer, more efficient, and higher quality. A new era of collaboration between humans and machines begins here. We close the labor gap in casting production.

Learn more about our Vision

Industrial AI:

Artificial Liquid Metal Processing.

Our physical artificial intelligence evaluates the quality of the melt before each casting—in seconds, with maximum accuracy. Modern robotics performs precise, repeatable work steps and integrates seamlessly into existing production lines. All relevant process data flows into our AI system, enabling real-time predictions, optimizations, and automations.

- Industrial Robotics

- Collaborative robotics

- Humanoid robotics

Find out more about our Technology

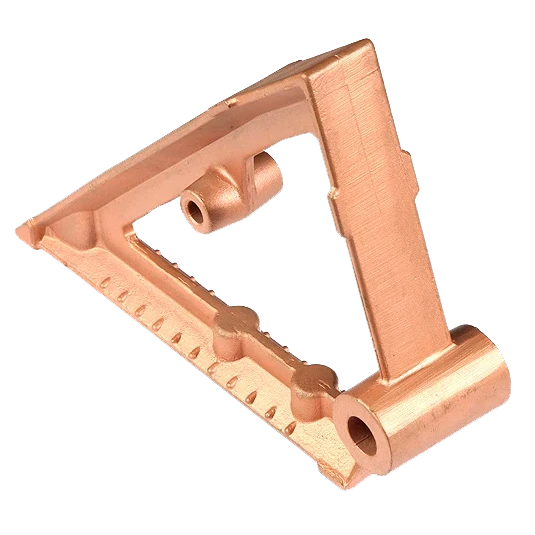

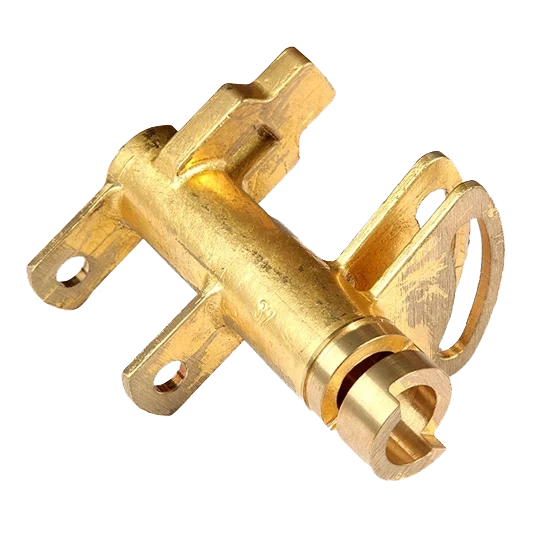

High Quality Castings

With modern casting technology, broad application expertise, and the versatile PIAD material range, we meet the highest requirements for conductivity, hardness, strength, corrosion resistance, and wear resistance. PIAD distinguishes between two material categories: conductive materials and construction materials, each suitable for different areas of application. The alloys can be roughly divided into copper, brass, and bronze. For each standardized material, there is an internal PIAD factory standard that sets significantly tighter tolerance limits and permissible impurities than the standard. This is how we ensure our consistently high casting quality—a decisive difference from competitors who do not have their own factory standards.