Robotics and AI in Casting

Vision – Pioneering the future of Casting with Robotics & AI.

Our response to demographic change: Industrial AI – physical artificial intelligence for the casting industry. Expertise in quality casting, state-of-the-art robotics, artificial intelligence and a dynamic team. Our solutions make casting processes safer, more efficient and higher in quality. A new era of collaboration between humans and machines begins here. We close the labor gap in casting production.

We are the first to consistently establish robotics and AI as a central vision for the future of casting. A foundry industry without monotonous, dangerous and physically demanding work—replaced by smart automation, maximum precision and outstanding efficiency. We develop technologies that not only meet today’s requirements, but set the standards for tomorrow.

Team – dynamic, technology-driven

Felix - CEO

Leads the company with a clear vision, strategic foresight and the ambition to sustainably transform the foundry industry through robotics and AI.

Markus - CTO

As the technical lead, drives the development of state-of-the-art robotics solutions and ensures that innovation is translated directly into fully functional industrial applications.

AI Expert - TBA

Develops the physical artificial intelligence that forms the core of our technology – from data analysis to intelligent production forecasting: the PIAD AI Agent.

Our team consists of engineers, developers and visionaries who share a common passion: rethinking technology and bringing it into practice.

We work in an agile, solution-oriented manner with a clear goal—to lead the foundry industry into the age of robotics and AI.

What drives us? Curiosity, courage and a strong commitment to sustainably transforming industrial processes.

Technology:

Our response to demographic change

Why casting?

Recycling. Energy Efficiency.

Casting is the most effective method to prodcue industrial parts.

Why Robotics & AI?

The World is short of Workers.

We are making the best possible use of this valuable resource.

Industrial Robotics

Performs heavy and monotonous work steps precisely and reliably.

Collaborative robotics

These so-called “cobots” work side by side with humans and can be used more flexibly for different tasks.

Humanoid robotics

Imitates human movements and interactions and can be flexibly integrated into existing production processes.

From over 100 years of casting excellence, we are shaping the future with Robotics & AI.

PIAD Casting

We launch our innovations on a solid foundation of foundry technology. Casting is the most effective method for manufacturing industrial components. The environmentally friendly processing of high-temperature metals in reusable molds offers considerable growth potential. At the end of their life cycle, castings are recycled by being melted down and processed into new castings.

Casting is the foundation—but the industry needs fundamental changes to cope with external factors. We provide answers.

PIAD Robotics

The foundry industry faces a double challenge: on the one hand, the complexity of products and processes is constantly increasing, while on the other hand, demographic change is exacerbating the shortage of skilled workers. Many qualified employees are retiring, while at the same time fewer young people want to enter physically demanding industrial professions.

Relief from heavy and repetitive work

Robots take over physically demanding tasks such as handling hot metals or heavy molds.Increased efficiency and precision

Automated systems ensure consistently high quality and enable higher productivity despite declining human resources.Attractiveness for young talent

The combination of traditional foundry knowledge with innovative robotics creates modern workplaces that attract tech-savvy talent.Future-proofing

The integration of robotics and AI will make the industry more resilient to demographic change and enable it to continue producing competitively in the future.

State-of-the-art robotics thus plays a decisive role in counteracting staff shortages resulting from demographic change while at the same time securing the innovative strength of the foundry industry.

Modern robotics handles precise, repeatable work steps and integrates seamlessly into existing production lines. We differentiate between:

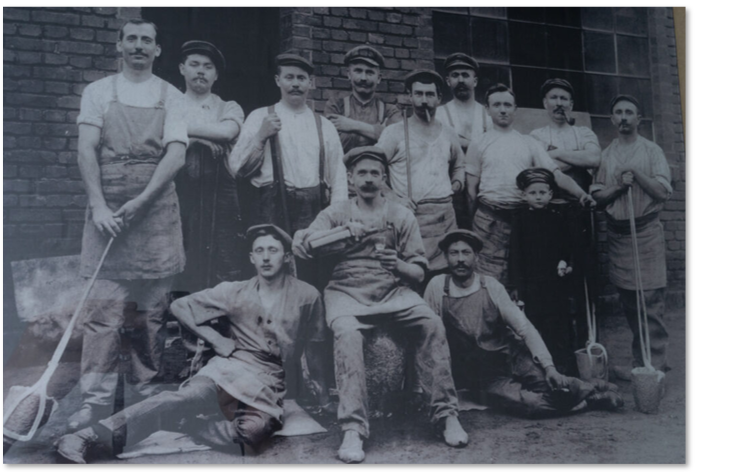

PIAD Artificial Intelligence Agent

PIAD casters were considered the best copper casters of their time because they combined perseverance, precision craftsmanship, and a deep understanding of materials and processes like no other team.

Their exceptional expertise, built up over decades and passed down from generation to generation, shaped not only the quality of their work, but the entire industry.

PIAD AI Agent – Today, this wealth of experience and knowledge flows into our PIAD AI Agent—a digital representation of the collective expertise of the golden age, combining state-of-the-art technology with the legendary skills of the PIAD casters.

Our PIAD AI Agent collects and analyzes all production data. All relevant process data flows into our AI system, enabling real-time predictions, optimizations, and automations. PIAD AI Agent evaluates the quality of the melt before each casting—in seconds, with maximum accuracy. It generates automatic quotes, predicts optimal manufacturing parameters, and thus increases efficiency and quality. With our solution, you not only get advanced technology, but also a holistic approach that unites safety, productivity, and quality.

Welcome to the new era of the foundry industry

Safer. More efficient. Smarter.