PIAD casting

PIAD casting process: precision molded components made from copper and its alloys open up entirely new fields of application – far beyond the well-known uses.

Chill casting produces ready-to-install structural components with precisely controllable material properties and clear economic advantages. The combination of material quality and dimensional accuracy continuously opens up new applications and markets for chill casting. Today, it is time to rethink the full potential of heavy-metal chill casting. In this process, components made of copper or copper alloys are cast into permanently reusable metal molds known as chills. Compared with investment casting and sand casting, this offers a decisive sustainability advantage.

PIAD Casting Process

“Chill Casting”

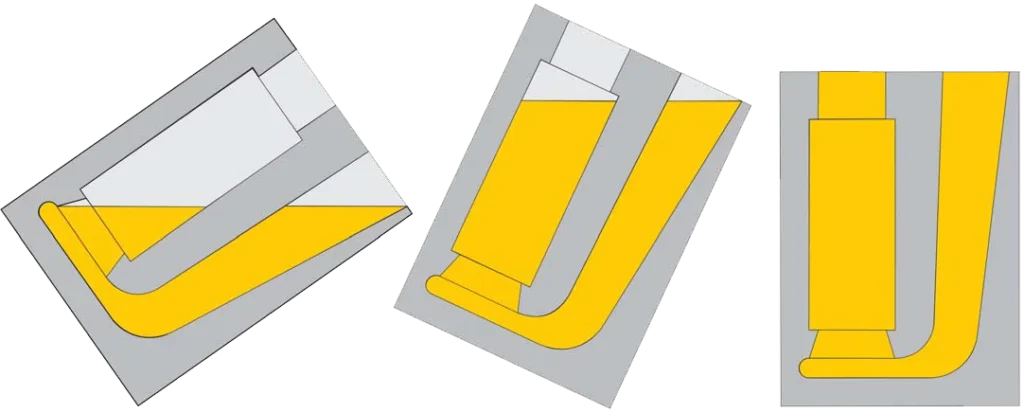

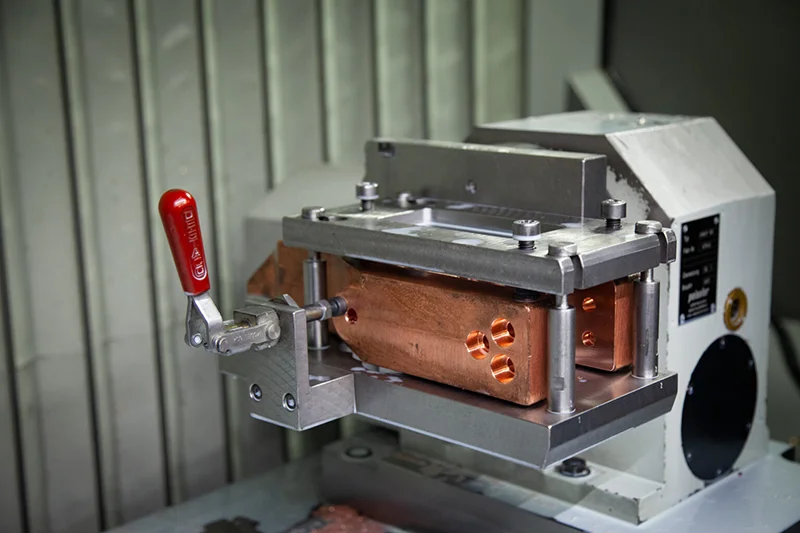

In the PIAD casting process, the mold is inclined toward the gating side at the start of casting and simultaneously returned to an upright position during filling. As a result, the molten metal experiences a reduced drop height and a low-turbulence filling process without air inclusions.

After demolding the cast component, the mold is immersed to cool it down to the required temperature and to coat the metallic surface with a release agent.

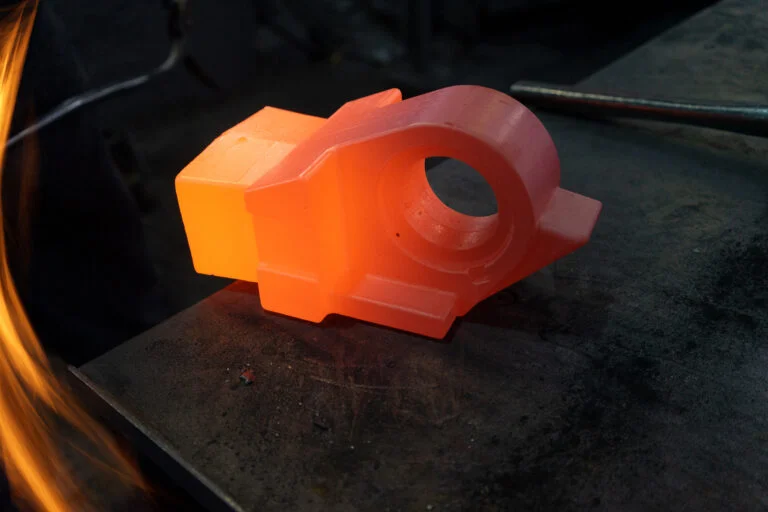

Due to the excellent thermal conductivity of the mold, the solidification of the molten material takes place within just a few seconds. As a result, the cast component is characterized by a very fine-grained, dense microstructure. This leads to superior mechanical, electrical and thermal properties compared with competing casting processes such as sand casting and investment casting.

Structure of the PIAD Casting Process

Robo Chill Casting (Robocasting)

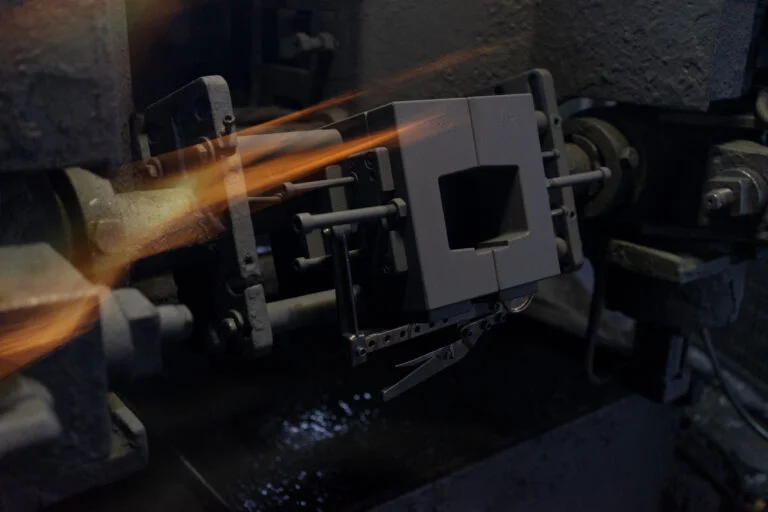

Instead of the employee performing the casting operation manually, a robot takes over this task – precisely, consistently and reliably. This results in clear advantages in terms of efficiency, quality and future viability. Robo chill casting combines human expertise with state-of-the-art robotics. It creates a production environment that is attractive to skilled professionals, as monotonous and physically demanding tasks are automated while employees’ know-how and process expertise can be applied in a targeted manner. This makes the process a key technology for the foundry of the future.

Machine Chill Casting

In contrast to Robo chill casting, in machine chill casting the employee continues to carry out the actual casting operation manually – albeit in close cooperation with a casting machine. The process combines human know-how with mechanical assistance and has been a reliable standard in foundry technology for decades. In machine chill casting, the molten metal is poured manually by the caster into the prepared mold. The machine primarily supports precise guidance, the closing and opening of the mold, as well as movements and cycle sequences. As a result, the caster’s experience remains central while being complemented by mechanical precision.

Manual Chill Casting

Manual chill casting is the most original form of chill casting and relies on close cooperation between two employees. The caster manually pours the molten metal into the mold, while a second employee supports the process – for example in handling, opening and closing the mold, or performing quality checks. This method is particularly suitable for small batch sizes and can be used economically from around 100 cast components. Manual chill casting is therefore the right choice when prototypes, pre-series or individual customer orders are to be produced.

Beyond these processes, we are also able to offer low-pressure chill casting, squeeze casting and die casting using copper and copper alloys.

All upstream and downstream process steps required for a PIAD quality cast component are carried out in-house.

Direct access to all stages of the value chain guarantees the consistently high quality of PIAD cast components.

Simulation, Design, Mold and Tool Making

At PIAD, all molds are designed to be casting-optimized and are subsequently manufactured in our mold and tool making department. PIAD benefits from extensive know-how in mold design, including the necessary casting simulations. The correct selection of suitable mold materials, depending on the geometry of the cast component, plays a crucial role in this process.

The correct adjustment of the alloys within the narrow limits of the PIAD internal standard is ensured on a daily basis before and during production using spark emission spectrometers.

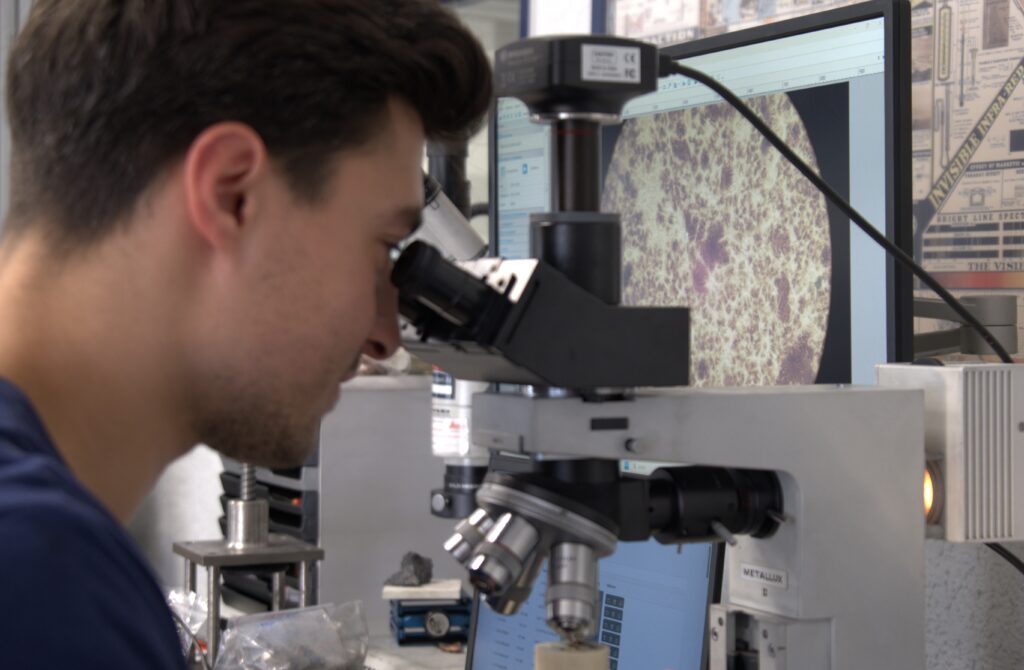

Microstructure analysis

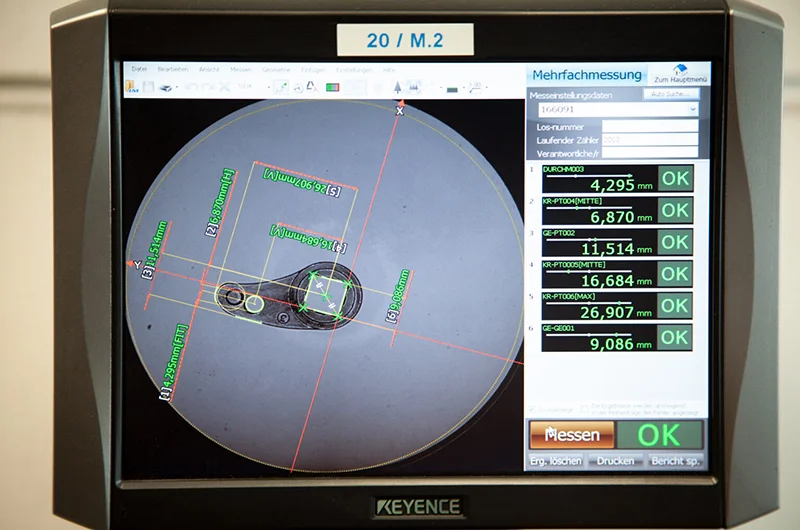

As part of ensuring microstructural quality, material-related parameters such as grain size distributions, intermetallic phases or precipitates are examined during production using metallographic cross-sections.

Heat treatment

Sawing, grinding, deburring

Sawing

Grinding

Deburring

CNC machining

Density measurement (X-ray, density balance)

The cast components are subjected to X-ray inspection and density measurement based on the Archimedes principle in order to ensure low-porosity casting.

After production of the ordered quantity of cast components, each mold is stored together with the final casting. Within a jointly agreed number of years, the customer may order additional parts from the same mold at any time.