Company

2020 - present

“With robotics and AI, we are shaping the future of die casting – making it more precise, more efficient, and more intelligent. Based on our deep-rooted expertise in alloy and process technology, we combine decades of experience with modern robotics and AI technology to set new standards in quality and productivity for our customers and to solve the challenges of demographic change.”

Felix Töberich, MBA

CEO

We share the goal of applying robotics and artificial intelligence to permanent mold casting in a sustainable way. We’re really focused on efficiency, delivery reliability, and quality.

History 1900–2020

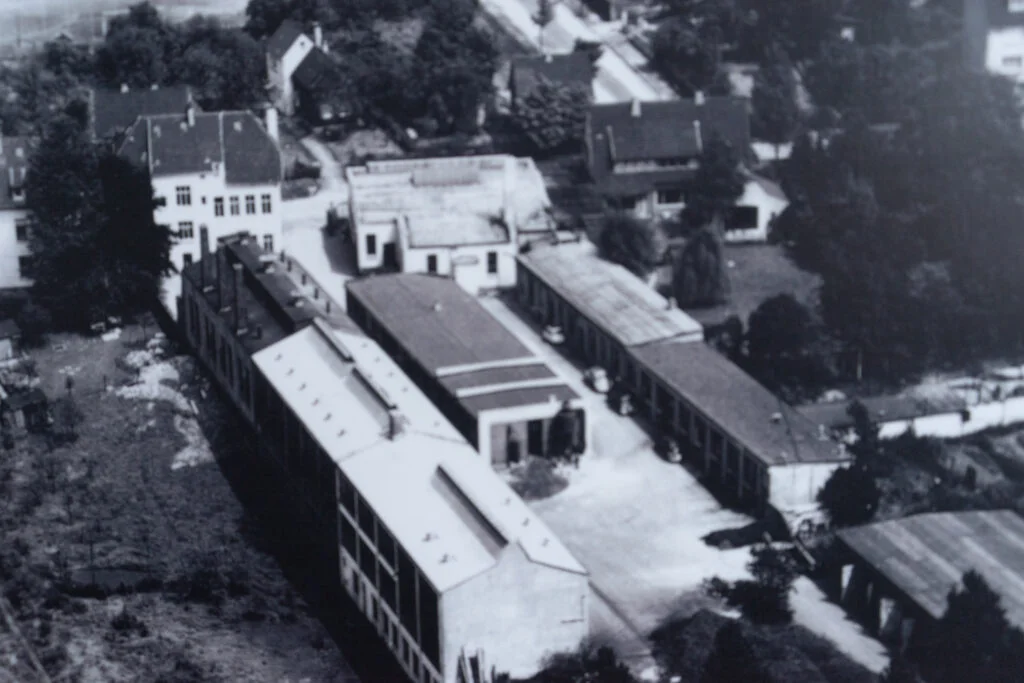

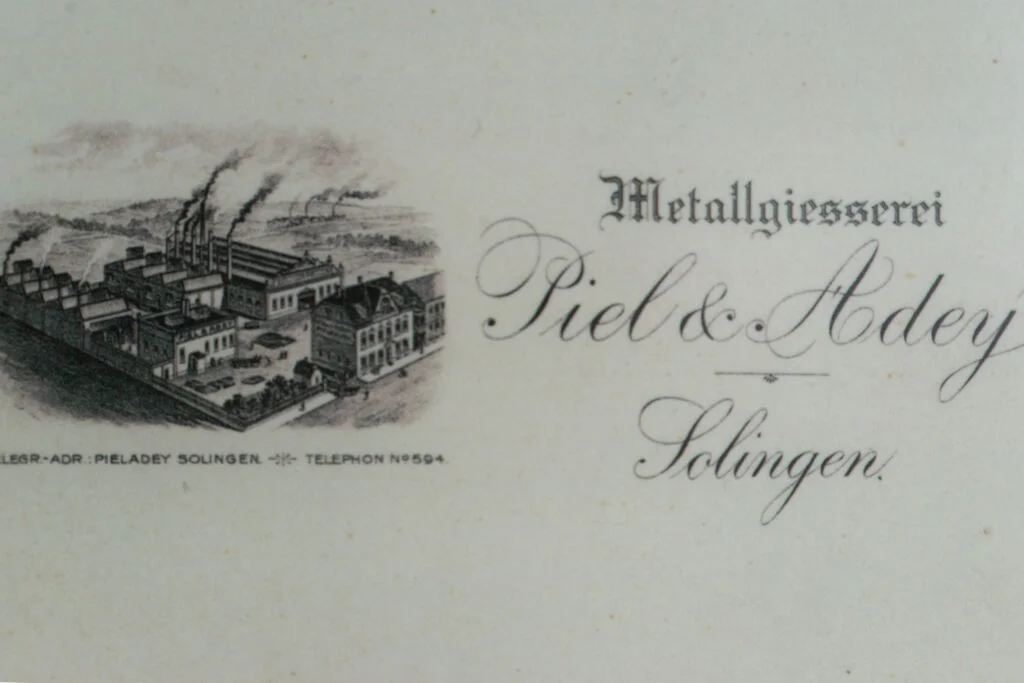

On May 1, 1900, Carl Adey and Carl Piel founded a metal foundry in Solingen. The order in which their names appeared was decided by drawing lots, and so the company was named Piel & Adey (PIAD).

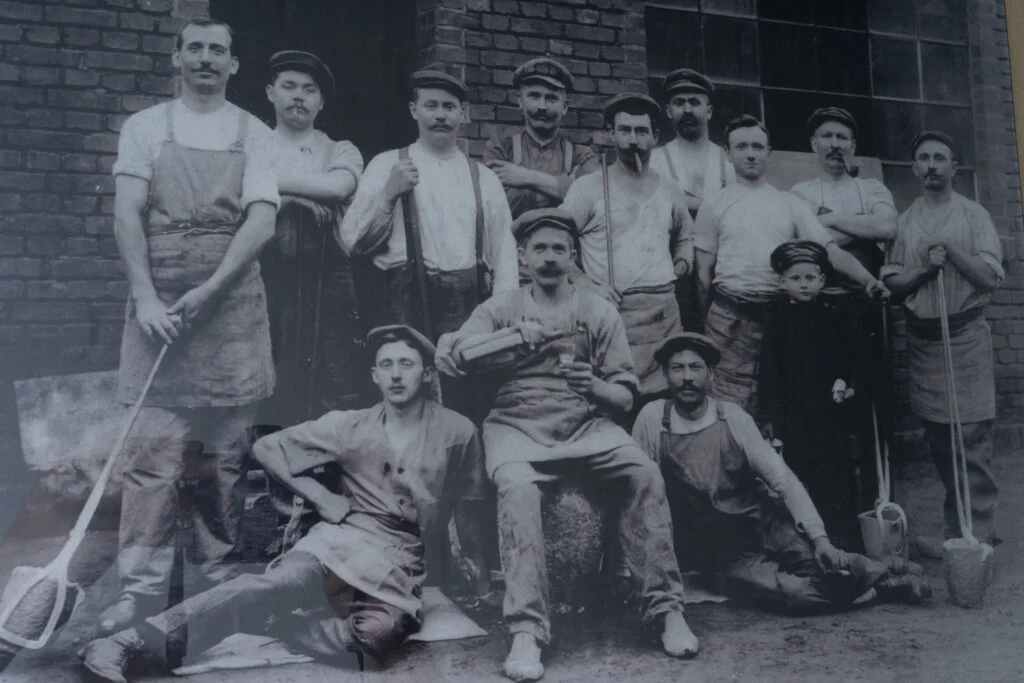

With perseverance and personal commitment, Carl Piel and Carl Adey had managed to build up the company from very small beginnings. Inventive spirit and a willingness to take risks led to success and important patents, ushering in the age of copper chill casting. The casting of copper and copper alloys in tilted molds was invented by Piel & Adey and became known as the PIAD tilting casting process or “chill casting.”

The company is guided by one fundamental principle: nothing has to stay the same just because it has always been done that way. We must constantly seek out and test new and better methods that are simpler, more effective, and more economical, while at the same time making work easier, especially for foundry workers. This fundamental principle has been a recurring theme throughout the company’s history, from its beginnings to the present day.

The first patent was granted on September 17, 1912, and many more patents followed. Here is just a small selection of the many patents:

- Patent No. 553551: Process and mold for producing castings from high-melting metals, in particular copper alloys.

- Patent No. 674711: Process for producing finished castings from copper alloys in continuous operation using metal molds

Patent No. 480900: Process for producing shaped metal parts from refractory alloys containing more than 50% copper by casting in a mold. - Patent No. 547969: Process for producing sharply defined molded or finished castings from refractory metals in molds.

- Patent No. 676438: Method for coating the inner wall of metal molds by dipping.

Patent No. 748017: Multi-part mold or core part for producing finished castings from non-ferrous heavy metals. - Patent No. 738996: Method for coating the inner wall of metal molds with insulating materials.

- Patent No. 892820: Method and apparatus for casting in molds, in particular for producing permanent mold castings. –Rising casting method by pushing the liquid metal upward through a displacement body.

Restructuring of the shareholder structure in 2020 – basis for innovation and investment

This was followed by a long and very successful period of expansion. PIAD chill casting became the global industry standard.

When the company’s succession was not secured after approximately 120 years, the shareholder structure was reorganized in 2020 as part of an asset deal, which forms the basis for the consistent future orientation. The alloy and process knowledge has been passed down through generations and was transferred to the respective owners in strict secrecy. A stable foundry technology foundation on which a new generation of engineers and thought leaders can build.